Cold chain packaging systems: Comparison of active, passive and hybrid thermal systems

A look at the advantages and disadvantages of the different types of thermal packaging systems

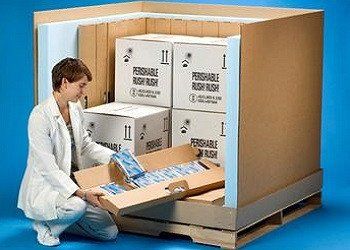

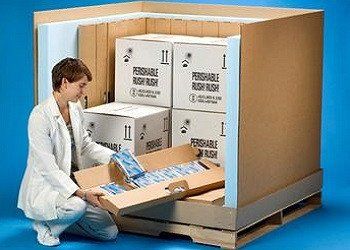

Cold chain packaging systems are designed to maintain sensitive products at the correct temperature (i.e. cold, warm, frozen, etc). There are three basic types of cold chain packaging systems available: active, passive and hybrid

Types of cold chain packaging

Each cold chain shipping system can be defined as follows:

Active systems: Active thermal systems do not use any phase change materials (PCM) such as water/ice or dry ice. These systems use mechanical or electric systems powered by an energy source, combined by thermostatic control to maintain proper product temperatures.

Passive Systems: Passive thermal systems commonly use phase change materials (PCM) such as water/ice or dry ice. These shipping systems are the most basic and cost effective.

Hybrid Systems: Hybrid thermal systems use a combination of PCMs such as water/ice or dry ice and thermostatic controls. These systems typically use PCMs as a source of energy, which is regulated by thermostatic control to maintain proper product temperatures.

The pros and cons of cold chain packaging

The following section highlights some of the advantages and disadvantages of each of the types of thermal packaging systems by attribute.

Size availability: Active and hybrid shippers, due to their increased complexity and cost, are available in a narrower selection of payload sizes, when compared to passive shippers.

Cost: Active and hybrid shippers due to their increased complexity are typically very costly, when compared to passive shippers.

Temperature accuracy: Active shippers have the highest temperature accuracy and hybrid shippers are second best. Passive shippers have the least accuracy and are least capable of maintaining narrow temperature ranges.

Thermal flexibility: Active shippers provide the greatest flexibility when a shipping system is exposed to a temperature profile different from the qualification temperature profile.

Shipping cost: Active and hybrid systems are typically more costly to ship due to their larger and heavier size.

Reliability: Active shippers typically have the most moving parts and maintenance requirements, while hybrid and passive shippers have few or no moving parts that can fail during transit.

Ease of use: Active and hybrid shippers shippers are easy to set up, but may require maintenance while in transit, depending on the shipment length. Passive shippers require pre-conditioning and specific assembly processes, but do not require maintenance while in transit; however shipment length is more limited with passive shippers because of phase change limitations.

Distribution flexibility: Active and hybrid shipping systems require a closed distribution loop and are re-usable. Passive shippers can be re-usable or disposable.

Hazard: Active shippers may use lithium batteries, and hybrid shippers may require dry ice. Passive shippers using water based PCMs do not pose hazard issues, but custom PCMs may pose toxicity or transport restrictions.

Examples of thermal packaging solutions

In summary, active thermal systems provide:

- Highest cost

- Highest temperature accuracy

- High reliability

- Standard/off the shelf sizes only - no custom sizes feasible

- Easy to use

The following are examples of active thermal systems:

Examples of thermal packaging solutions

In summary, active thermal systems provide:

- Highest cost

- Highest temperature accuracy

- High reliability

- Standard/off the shelf sizes only - no custom sizes feasible

- Easy to use

The following are examples of active thermal systems:

Passive thermal systems provide:

- Lowest cost

- Lowest temperature accuracy

- High reliability with proper procedures

- Standard/off the shelf & custom sizes may not require tooling

- Phase Change Material conditioning required - hardest to use

The following are examples of typical passive thermal systems:

Hybrid thermal systems provide:

- Moderate to high cost

- Moderate to high temperature accuracy

- Moderate reliability with proper procedures

- Standard/off the shelf sizes only - no custom sizes feasible

- Phase Change Material conditioning required - added complexity

The following are examples of typical hybrid thermal systems: